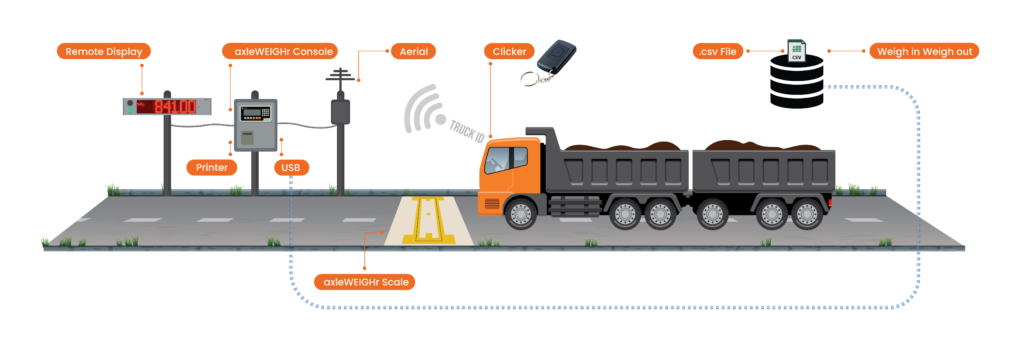

Rinstrum’s axleWEIGHr is a fast, accurate and economical way to monitor commodities that are coming into or leaving your facilities, and improve load capacity and safety.

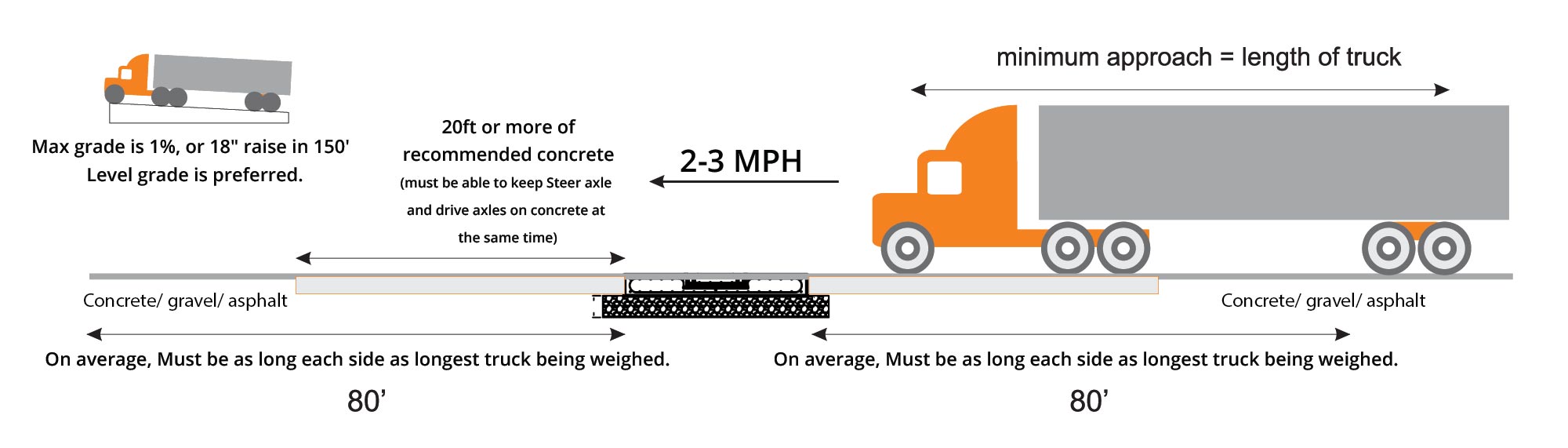

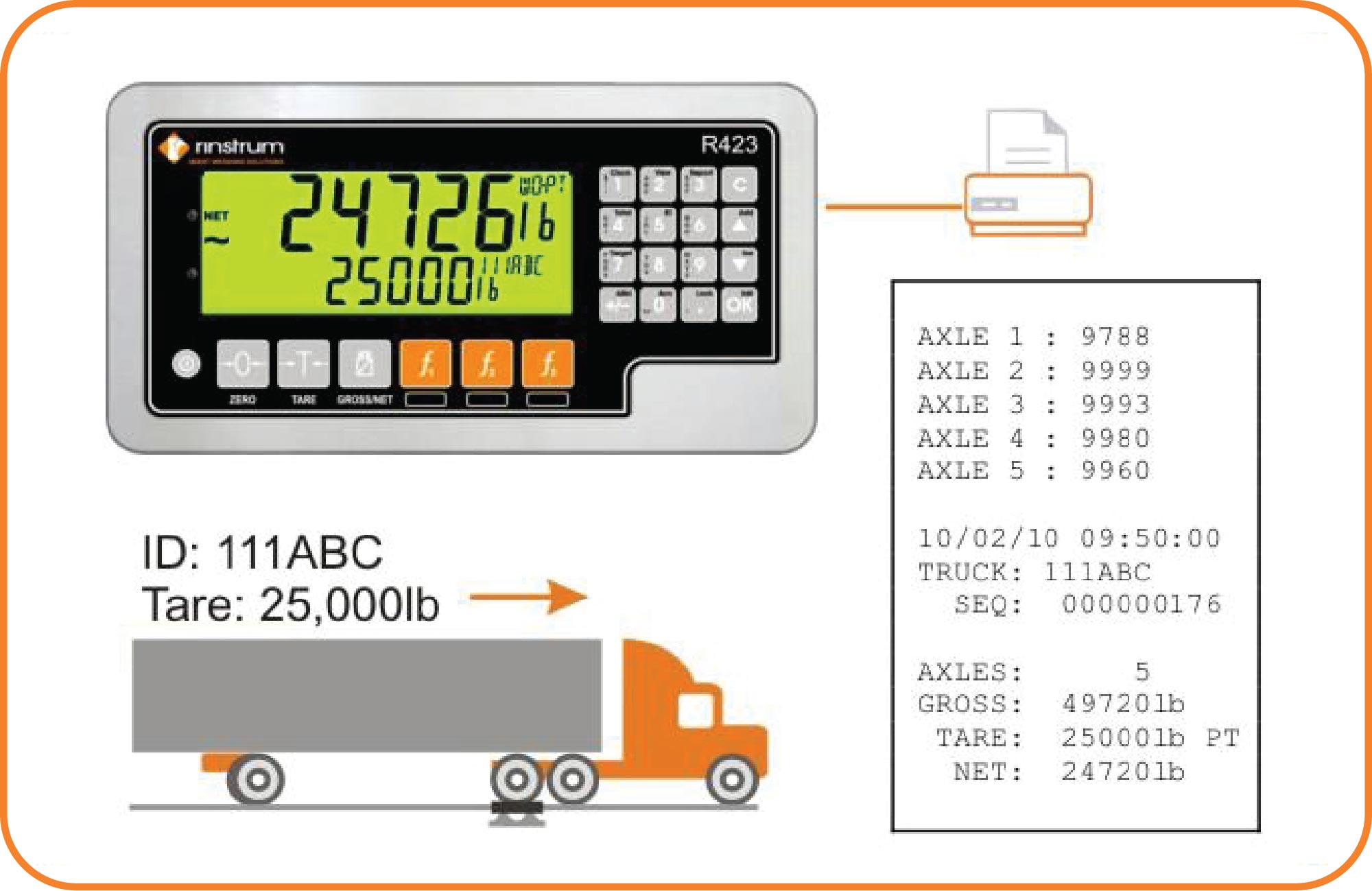

Drive over the scale while moving a constant 2-3 mph. The scale will automatically weigh each axle and can print a receipt with individual axle weights and the total GVWR ideal for CoR requirements. If you store the trucks ID and tare weight, or use 2 pass weigh in weigh out weighing, the controller will calculate the Gross, Tare and Net values.

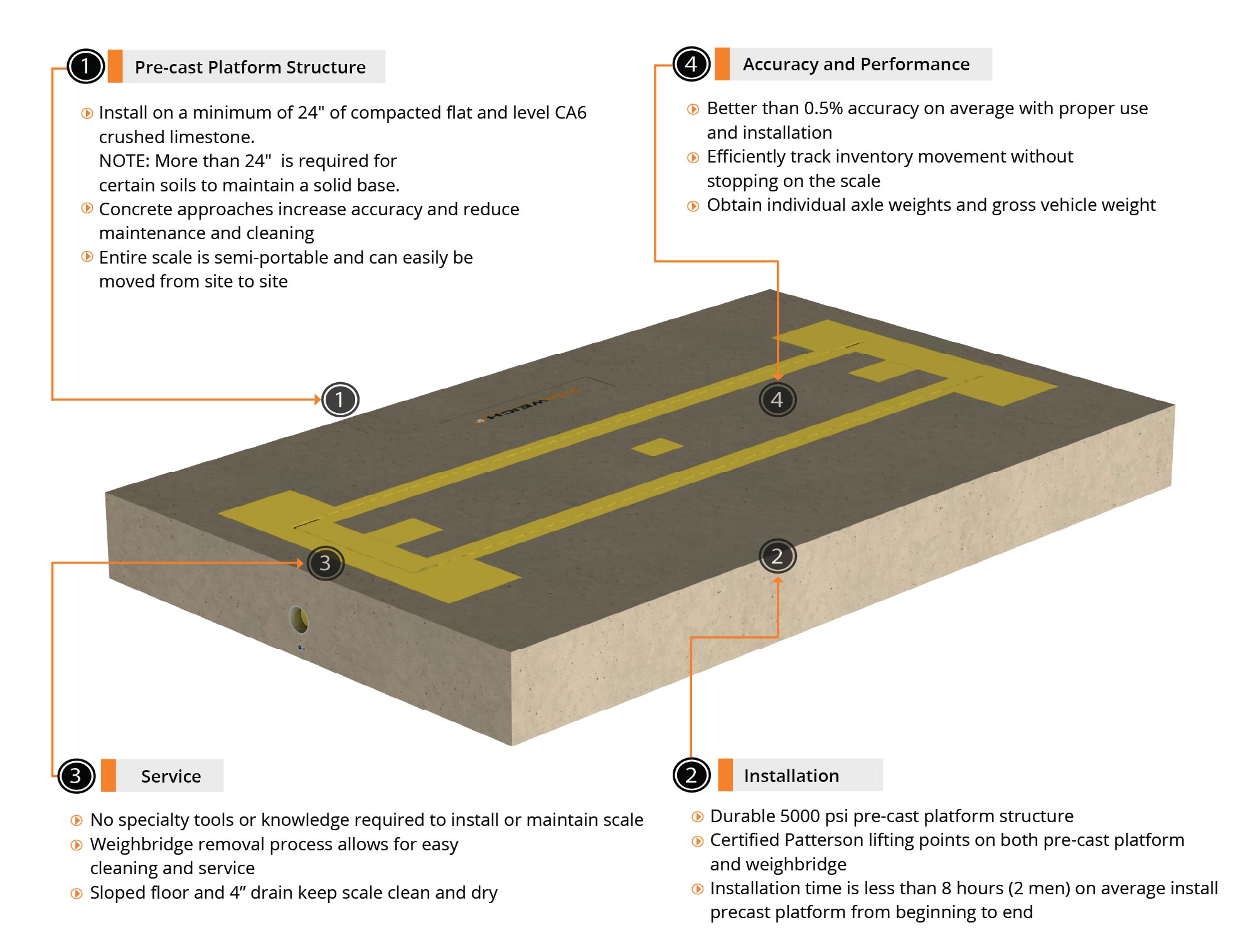

On average better than ± 0.5% accuracy can be expected. Company testing as well as extensive field trials have shown that with extended flat and level concrete approaches ± 0.2% or better accuracy can be achieved on average. Individual results may vary. Well maintained vehicles weigh the best.

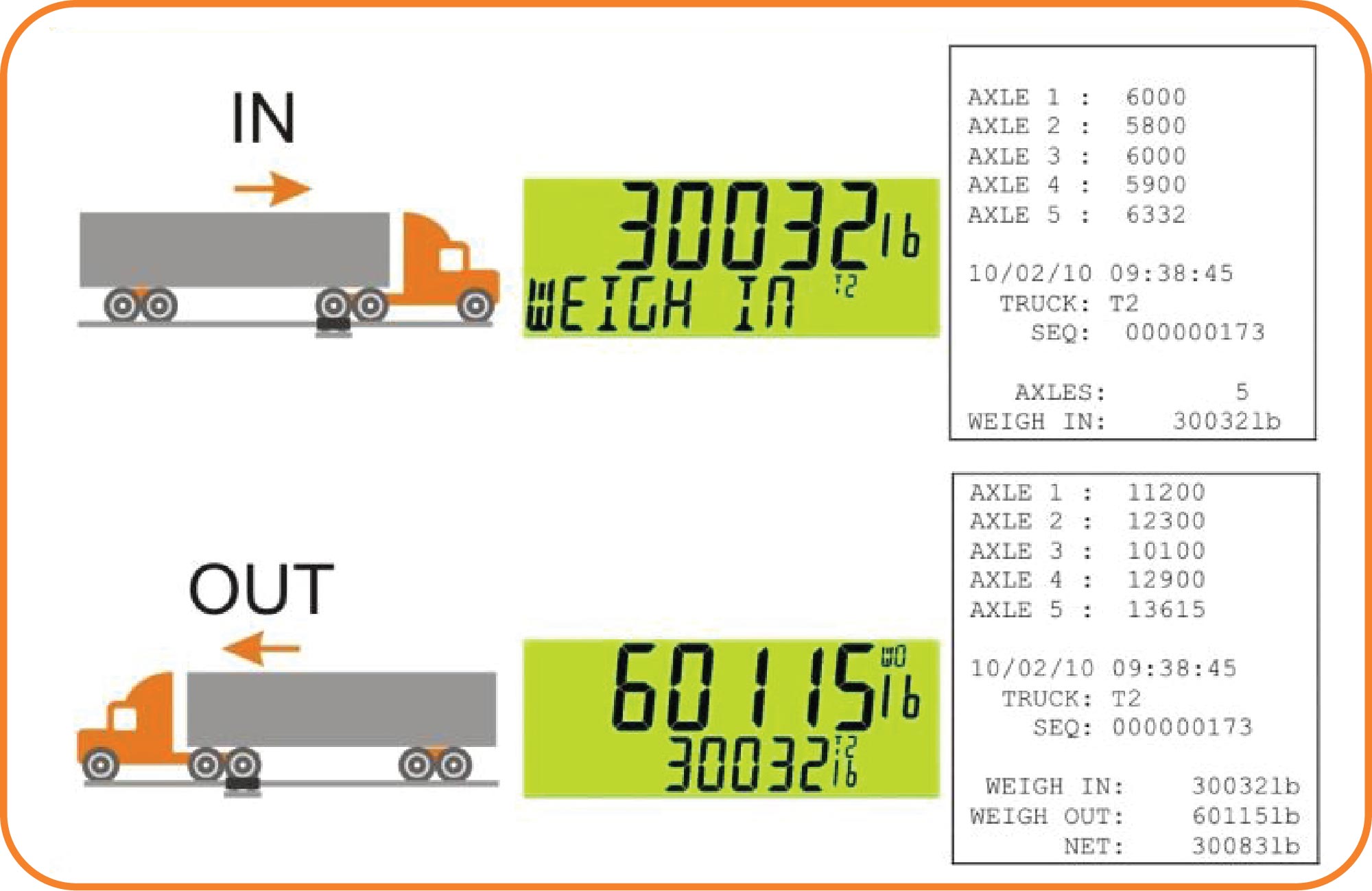

Two pass weighing - Weigh in and weigh out

INBOUND

Press the TRUCK key, select Truck ID then OK, or press CLICKER

Drive over the scale

OUTBOUND

Press the TRUCK key, select Truck ID then OK, or press CLICKER

Drive over the scale

Single pass weighing with known tare weight

Press the TRUCK key, select Truck ID then OK, or press CLICKER

Drive over the scale